Metallurgical blanks

AEM-Technologies has launched the production of large-sized metallurgical blanks for various industrial facilities. The unique equipment ensures the highest quality of castings and forgings, as well as enables manufacturing of the products of up to 23 m in length.

AEM-Special Steels is the only Russian manufacturer of metallurgical blanks for nuclear industry products.

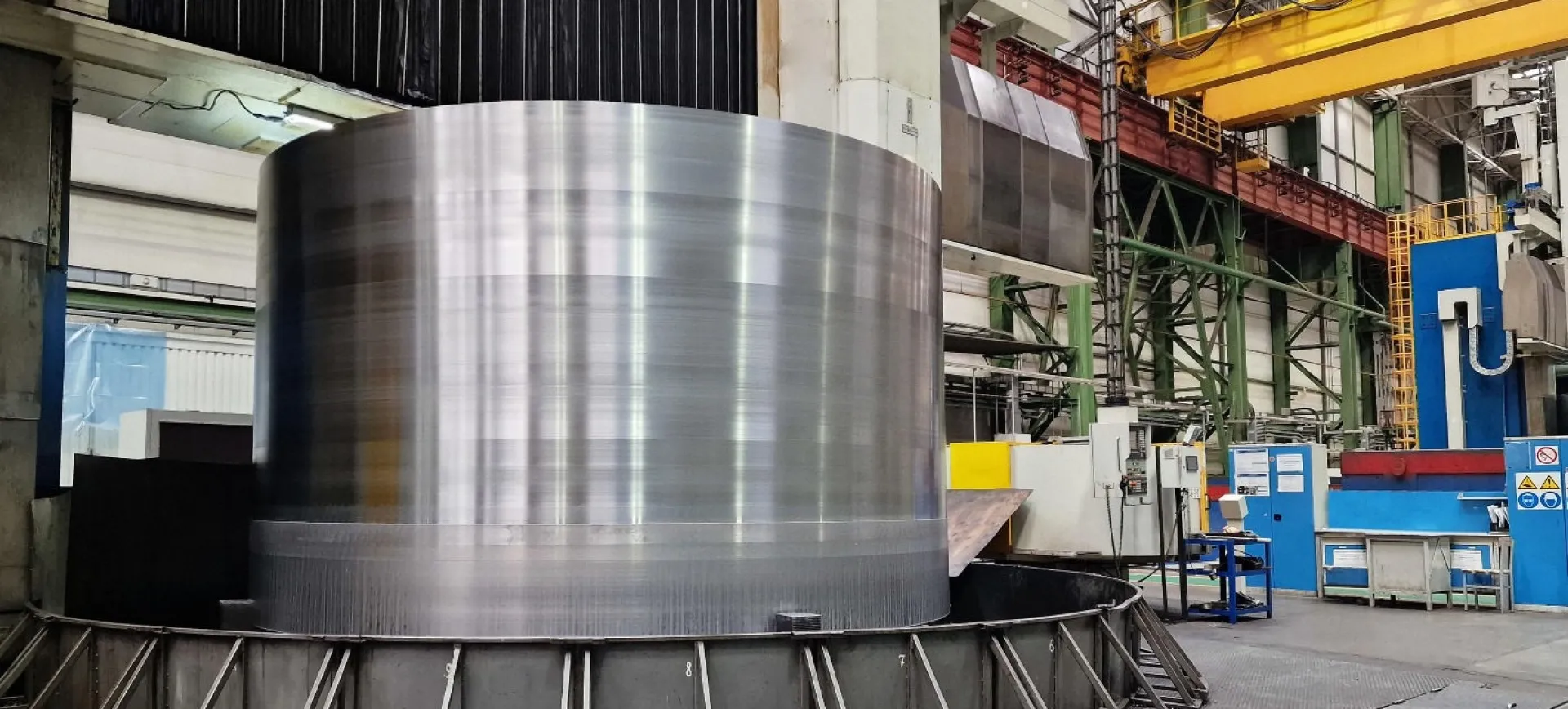

REACTOR PRESSURE VESSEL SHELLS

Reactor pressure vessel shells are cylindrical products made of high-strength steel; they belong to large-capacity metallurgical blanks for critical applications. Currently, they are supplied to the Russian-deisgned nuclear power plants under construction in China, Turkey, India, Bangladesh, and Egypt.

STEAM GENERATOR SHELLS

Steam generator shells are large-sized metallurgical blanks that are used to manufacture steam generator vessels. In total, four (2 central and 2 side) shells are required per one vessel. The blanks are connected to each other, then the bottoms are welded to the structure.

REACTOR PRESSURE VESSEL BOTTOM

A reactor pressure vessel bottom is a large-sized elliptical product that is one of the most difficult components in terms of production. It is made of high-strength steel of a certain composition and extremely homogeneous structure. This item has no welded joints.

In addition to the shells and bottoms of the power reactors and steam generators, AEM-Technologies manufacures components for RCPs and MCPs.

STEAM TURBINE ROTORS

Steam turbine rotors are large-capacity metallurgical products. AEM-Technologies produces steam turbine rotors up to 20 meters in length for nuclear (NPP) and condensing (regional) power plants, as well as central heating plants.

The company also manufactures other metallurgical blanks such as rotors for wind turbines, generator rotors, hydraulic shafts, housings, blades, impeller hubs, and cylinder casings.