Nuclear reactors

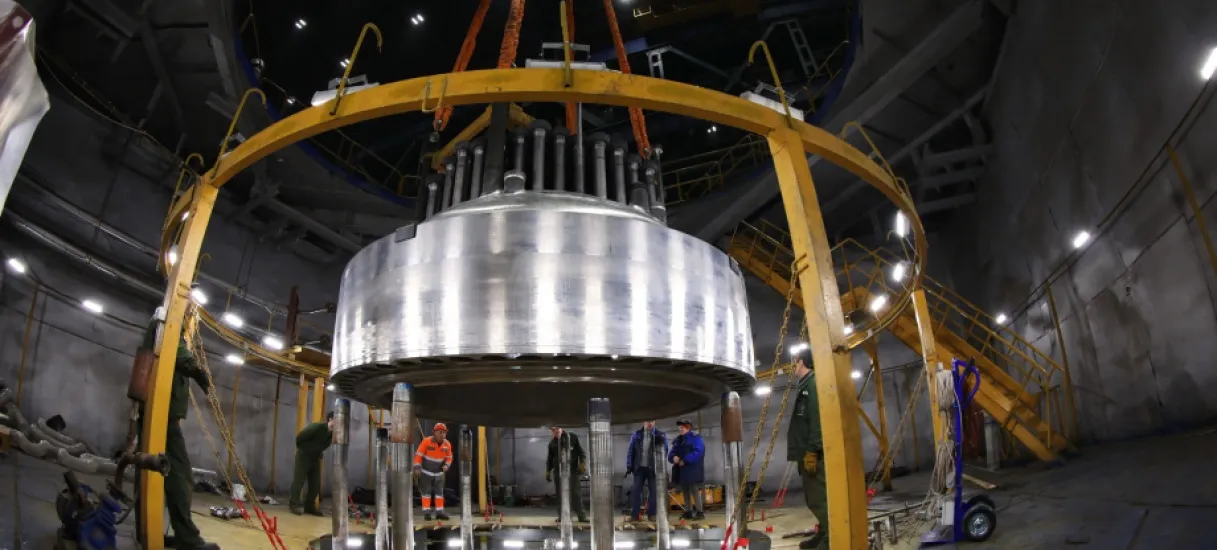

Manufacturing of water-cooled water-moderated power reactors is the key profile of AEM-Technologies. The high safety and reliability of the Russian-designed nuclear reactors allowed the company to take a leading position in the global nuclear energy market.

The current reactor generations combine the best developments in the industry and are in great demand among Russian and foreign customers.

AEM-Technologies produces water-cooled water-moderated power reactors VVER-1000, VVER-1200, and VVER-TOI. Each generation has individual advantages and the common key one is high reliability, which can be achieved through application of the up-to-date quality management methods, use of the unique equipment and constant development of technologies.

VVER-1000 is a time-proved and, today, most common reactor in the world. VVER-1200 is a flagship development with improved technical characteristics, higher power, and enhanced safety systems. VVER-TOI is the latest generation of Russian-designed reactors, a product with the best technical and economic parameters, targeted for promotion at the international market.

|

Thermal power

| 3 000 – 3 300 MW |

|

Electric power

| 1 000 – 1 255 MW |

|

Сapacity factor

| 80 – 93% |

|

Maximum fuel burnup

| 68 – 70 MW·day/kg |

|

Number of fuel assemblies

| 163 |

|

Number of control rods

| 61 – 121 |

|

Coolant pressure at reactor core outlet

| 15.7 – 16.2 MPa |

|

Fuel weight in reactor core

| 85 950 – 87 065 kg |

|

Efficiency

| 33 – 37.9% |

|

Reactor pressure vessel height mm

| |

|

Reactor pressure vessel weight tons

| |

|

Weight of reactor pressure vessel with internals (shaft, baffle, and protective pipe spool) tons

| |

|

Maximum thickness of reactor pressure vessel wall mm

|