Petrozavodskmash launched cladding of blanks for pipelines of China NPP

Petrozavodsk Branch of AEM-Technologies, JSC (a member of Atomenergomash, the machine building division of Rosatom State Corporation, and Karelian Regional Branch of the Russian Engineering Union) has started cladding main coolant pipelines (MCP) of Tianwan NPP (Unit No. 8) and Xudapu NPP (Unit No. 4). The nuclear power stations are being built in the People’s Republic of China.

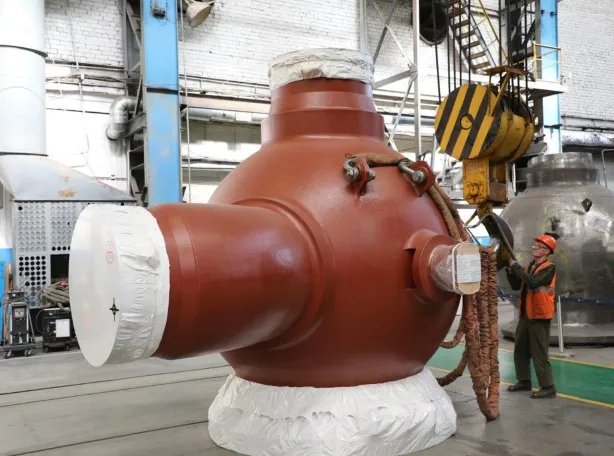

An anticorrosive clad layer is deposited on the pipe inner surface by electroslag welding at Petrozavodskmash. All the blanks to be used for manufacturing bends, which include 12 pipes for bent MCP sections, and the first pipe of the pipeline straight section for Tianwan NPP have already been clad. The first two bend blanks have been deposited for Xudapu NPP. Totally there will be 36 pipes clad for each power unit, which later on will be assembled into 16 MCP spools. Sets of rings for welding procedure qualification and certification of welders on site will be overlay welded as well.

MCP, which inner diameter is 850 mm and total length is 146 meters, connects the main equipment of the NPP primary circuit: the reactor, steam generators and reactor coolant pumps. It is intended for primary circuit coolant circulation at a temperature up to 330 degrees Celsius under a high pressure of 160 atmospheres. To protect the pipes from any aggressive effect of the coolant, an anticorrosive coating is applied to the inner surface of forged blanks. It bears reminding that Petrozavodskmash was the first in Russia to master the manufacturing process of seamless clad pipes for nuclear power plants.

Tianwan NPP is situated in Jiangsu Province of China. Xudapu NPP is located in Liaoning Province, Northeast China. Tianwan NPP, stage 3, and Xudapu NPP, Units 3 and 4, are being constructed under the NPP-2006 project , and comply with the current IAEA requirements in terms of safety.

Russia is consistently developing international trade and economic relations focusing on cooperation with friendly countries. Despite external constraints, the domestic economy is building up its exporting potential, and providing goods, services and raw materials all over the world. Atomenergomash, JSC takes an active part in these activities.