Petrozavodskmash started manufacture of safety system hydroaccumulators for Akkuyu NPP

Petrozavodsk plant of AEM-Technologies, JSC (a member of Atomenergomash, machine engineering division of Rosatom Corporation, and Karelian Regional Branch of the Russian Engineering Union) has started the manufacture of hydroaccumulators of passive core flooding system (PCFS hydroaccumulator) for the fourth Power Unit, Akkuyu NPP (Turkey).

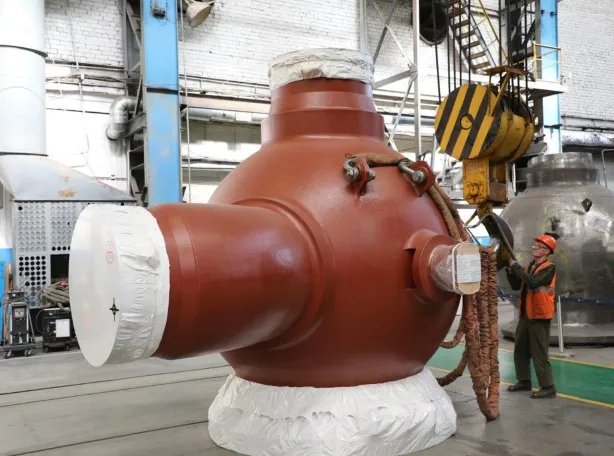

Shells for the assembly of hydroaccumulator bodies are manufactured in the assembly-and-welding facilities of Petrozavodskmash. Each PCFS hydroaccumulator consists of three shells and two bottoms. The shells are made of 60 mm thick stainless steel rolled sheets. In order to make one part, a 2.5 meters wide and 13 meters long blank is bended on a machine into a cylinder with the diameter of 4.3 meters. For the set of eight hydroaccumulators of PCFS, 24 shells shall be manufactured.

The passive core flooding system belongs to NPP passive safety systems and it is designed to remove the residual heat of the primary circuit coolant. The system comprises of 8 hydroaccumulators, each having a capacity of 120 cubic meters. An aqueous boric acid solution heated to a temperature of approximately 60 degrees is stored inside the hydroaccumulators at the plant during operation. When the pressure in the primary circuit falls below a certain level, the fluid is automatically fed into the reactor and the active core is cooled down.

Akkuyu NPP in Turkey is the first nuclear-industry-related project in the world being implemented pursuant to BOO (“build-own-operate”) approach. The project includes four Power Units equipped with Russian 3+ generation VVER-reactors with increased safety and advanced technical and economic characteristics. Design of the object is carried out by the Engineering Division of the Rosatom State Corporation. Each NPP Power Unit will have capacity of 1200 MW.

Russia is consistently developing international commercial and economic relations, focusing on cooperation with friendly countries. Despite the external constraints, the domestic economy is increasing the export opportunities and delivering goods, services and raw materials globally. Atomenergomash, JSC is substantially involved in this activity.

Based on the intergovernmental agreement concluded between the Russian Federation and the Republic of Turkey, the first NPP Power Unit shall be commissioned within 7 years after all the permits and licenses for the Unit construction are received. With respect to receiving the license for the construction of Power Unit No. 1 in 2018, it shall be 2025. Moreover, all the project participants are exerting all efforts to complete the construction of the first Power Unit and provide the readiness for the starting tests in 2023, the anniversary year for the Republic of Turkey.