Petrozavodskmash shipped steam generator headers for Tianwan NPS

Petrozavodsk plant of AEM-Technologies, JSC (a member of Atomenergomash, machine engineering division of Rosatom Corporation, and Karelian Regional Branch of the Russian Engineering Union) manufactured the primary circuit header bodies designed to complete steam generators of power unit No. 7 of Tianwan NPS under construction in China.

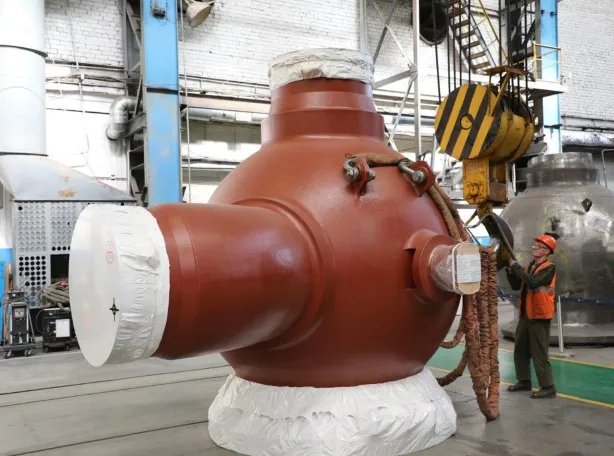

Header body is a component of the steam generator and relates to the first safety class equipment. Delivery set for one Power Unit is 8 primary circuit header bodies - two per each of four steam generators. Header is a thick-walled cylinder of variable diameters and thickness. Total height of the item is more than 5 meters, maximum diameter exceeds 1 meter with the wall thickness of 171 mm. Through the header, heat exchange between primary and secondary coolant circuits of reactor facility goes and heat is removed from the reactor core.

Anticorrosive overlay is applied on the inner surface of the header by strip in two layers. More than 2 tons of welding materials are used for one item during welding and overlaying, the weight of the finally manufactured header exceeds 16 tons. At each stage of the manufacture there is a quality inspection including visual and dimensional inspection, penetrant test, ultrasonic inspection, and radiographic test.

Tianwan NPS is located in Jiangsu Province, PRC. The first power units No. 1 and No. 2 with VVER-1000 reactors were accepted by the customer and put into warranty period operation in 2007. Units No. 3 and No. 4 were put into warranty period operation in 2018. In the same year, the intergovernmental report and framework contract for the construction of power units No. 7 and No. 8 of Tianwan NPS with VVER-1200 reactors relating to the latest generation “3+” were signed.

Russia is consistently developing international commercial and economic relations, focusing on cooperation with friendly countries. Despite the external constraints, the domestic economy is increasing the export opportunities and delivering goods, services and raw materials globally. Atomenergomash, JSC is substantially involved in this activity.