Petrozavodskmash manufactured pipeline valves for Rooppur NPP

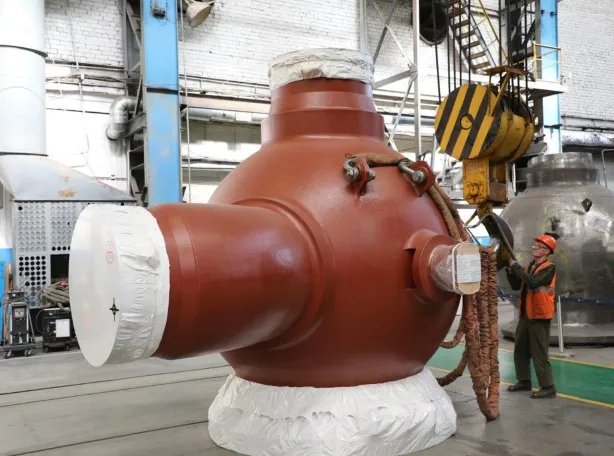

Petrozavodsk Branch of AEM-technologies, JSC (a part of Atomenergomash, the machine-building division of the Rosatom State Corporation, and a member of Karelian Regional Wing of the Russian Engineering Union) manufactured stop valves of up to 600 mm diameter, intended for equipping the reactor hall of power units No. 1 and No. 2 of Rooppur NPP (the People’s Republic of Bangladesh).

The manufactured high-pressure wedge gate valves refer mainly to equipment of the second, as well as the third and fourth safety classes. In total, Petrozavodskmash produced 116 items with nominal diameter from 100 to 600 mm. The gate valves are designed for high loads — pressure up to 12 MPa and temperatures up to 300 ° C.

The gate valves passed the entire set of factory tests including pneumatic, hydraulic and leak tests. During the tests the equipment had been held under pressure of 18.4 MPa for 10 minutes.

Pipeline valves are a serial product for Petrozavodskmash manufactured following in-house design and process documentation. Such proprietary designs demonstrate the present day engineering resources of the domestic enterprises, have high export potential and contribute to strengthening the technological sovereignty of our country.

AEM-Technologies, JSC is the biggest manufacturing company within Atomenergomash, JSC – the machine-building subdivision of Rosatom State Corporation. Nowadays it is one of the leading Russian companies in the field of power machine-building and the only Russian fully integrated manufacturer: from the own production of semifinished metallurgical products to finished high-tech products of large dimensions that can be shipped to any part of the world. The company consists of an engineering center staffed with experienced designers and process engineers in Saint Petersburg and four manufacturing sites: Izhora and AEM-Special Steels in Saint Petersburg, Atommash in Volgodonsk, and Petrozavodskmash in Petrozavodsk.