Atommash has completed work upon carrying out the threaded holes on the Reactor vessel for Tianwan NPS

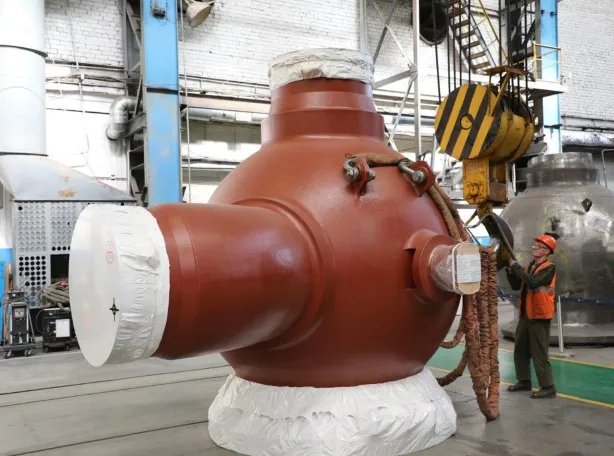

Atommash Branch, AEM-Technologies, JSC in Volgodonsk (part of the machine-building division of Rosatom - Atomenergomash) carried out the cutting of threaded holes of the main joint on the Reactor vessel for the seventh power unit of the Tianwan NPS in China.

Threaded holes are necessary for attaching the reactor main joint to the cover of the Upper unit, which is one of the determining factors for the safe operation of complex equipment. In 12 days, specialists formed a high-precision metric thread with a diameter of 170 mm on 54 holes.

After machining, the specialists carried out a bench work operation and brought the surface of the thread to an ideal mirror condition. The Quality Control Department confirmed the high quality of the work performed. During hydraulic tests, two-meter studs will be screwed into the holes and tightened with 50-kilogram nuts. The thread on the main joint ensures the complete tightness of the reactor.

Atommash is manufacturing four reactor plants with Internals and 16 Steam generators for the People's Republic of China.

The reactor is an item of the first safety class. It is a vertical cylindrical vessel with an elliptical bottom. The core and in-vessel devices are located inside the vessel. From above, the reactor is hermetically tightened with a Cover by means of the main joint studs.

Tianwan NPS is located in Jiangsu Province, China. The first power units No.1 and No.2 with VVER-1000 reactors were shipped to the customer and put into warranty operation in 2007. Units No.3 and No.4 were put into warranty operation in 2018. On June 8, 2018, an intergovernmental report and a framework contract for construction of power units No.7 and No.8 of the Tianwan NPS with VVER-1200 reactors, which refer to the latest generation "3+". The design and construction of the facility is carried out by the Engineering Division of Rosatom State Corporation. The capacity of each new NPS power unit will be 1200 MW.

***

AEM-Technologies, JSC is the largest manufacturing company in the structure of JSC Atomenergomash JSC, the machine-building division of the Rosatom State Corporation. It is one of the leading Russian companies in the field of power engineering and the only Russian company with a full manufacturing cycle: from its own production of metallurgical blanks to finished high-tech oversized products with the possibility of shipment to anywhere in the world. The structure of AEM Technologies JSC includes: an engineering center staffed by experienced designers and process-engineers in Saint Petersburg and four production branches: «Izhora» and «AEM-Special Steels» in Saint Petersburg, «Atommash» in Volgodonsk and «Petrozavodskmash» in Petrozavodsk.