Atommash has carried out a check assembly of Reactor vessel for Kudankulam NPP

Atommash Branch, AEM-Technologies, JSC in Volgodonsk (a part of machine-building division of Rosatom –Atomenergomash) has performed an assembly of the Reactor vessel with the Internals. The item is being manufactured for power unit No. 5 of NPP "Kudankulam" (India).

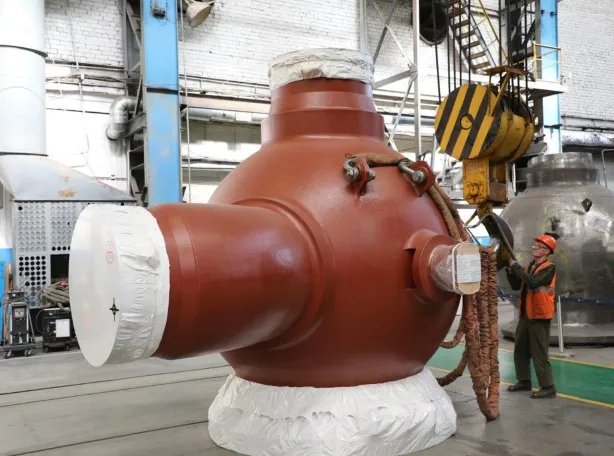

Check assembly was carried out in an underground caisson. First, using a crane with a lifting capacity of 600 tons, the specialists installed the 11-meter VVER-1000 Reactor Vessel on its design position. Then, one after another, they lowered the 10-meter long Core Barrel weighing 73 tons, the Core Baffle weighing 38 tons, and the Protective Tube Unit weighing 68 tons. The Reactor was then closed with the standard Reactor Cover. The total assembled weight of the item reached 603 tons.

During the assembly, the staff installed keys and fasteners on the Reactor Vessel and fixed the centering device of the Reactor cover. During check assembly, the items exactly repeat their design position. In this case it significantly reduces the deadline and simplifies the mounting of the Reactor facility at the NPP construction site.

Reactor is a vertical cylindrical vessel with an elliptical bottom, there is a core and Internals inside the item. From above, the equipment is sealed with a Cover with drives of mechanisms and control and protection units installed on it, nozzles for outputting cables of in-reactor control sensors.

Building of Kudankulam NPP in Tamil Nadu in the south of India includes the construction of six power units with VVER-1000 reactors type having capacity of 6000 MW. The first stage, consisting of power units No. 1 and No. 2, was included in the national power grid of India in 2013 and 2016, respectively. At the moment, the construction of power units No. 3, 4 and No. 5, 6, which are the second and third stages of Kudankulam NPP, is being performed.