Reactor pressure vessel for Xudapu NPS successfully passed hydraulic tests at Atommash

At AEM-Technologies Atommash (part of engineering division of “Rosatom” State Corporation - Atomenergomash) hydraulic test of the reactor pressure vessel for Unit 3 of the Xudapu NPS, which is under construction in China, was successfully completed. The tests were conducted in a three-level underground caisson, a special sealed shaft designed for such work.

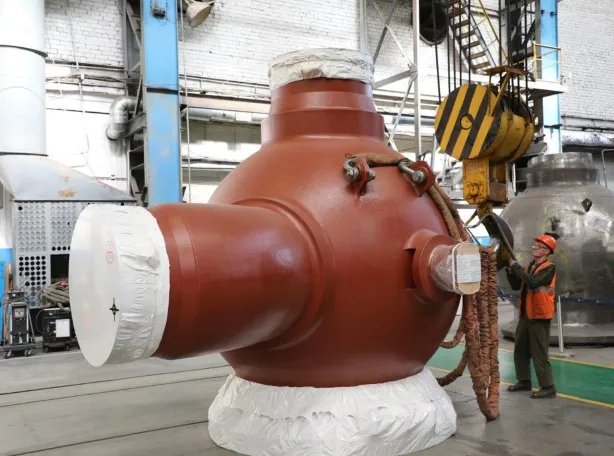

Using a crane with a lifting capacity of 600 tons, the support ring was first lowered into the stand, and then the 11-meter VVER-1200 reactor vessel was placed on it with an accuracy of 0.5 mm. To create complete sealing, plugs and top head were used, which were connected to the reactor pressure vessel using 54 main joint studs. During the tests the item was filled with distilled water, heated to 100 degrees and created the maximum pressure (24.5 MPa) - this is 1.4 times higher than the working pressure.

As a result, the equipment confirmed the strength of the base metal and welded joints. The reactor is a vertical cylindrical vessel with an elliptical bottom, inside which the core and internals are located. The top of the equipment is hermetically sealed with a top head with the actuators of mechanisms and control and protection devices installed on it, nozzles for output of cables of in-reactor control sensors.

Atommash will manufacture two reactor pressure vessels with internals, top head and upper unit and two sets of steam generators for Units 3 and 4 of the Xudapu NPS. The Xudapu NPS is located in Liaoning Province, China. Power units 3 and 4 are being built under the NPP-2006 project and meet modern IAEA safety requirements.

The facility is designed and built by the Engineering Division of Rosatom State Corporation. Russia consistently develops international trade and economic relations, focusing on cooperation with friendly countries. Despite external restrictions, the domestic economy is increasing its export potential and supplies goods, services and raw materials around the world. JSC Atomenergomash takes an active part in this work.

AEM-Technologies JSC is the largest company in the structure of Atomenergomash JSC, the machinebuilding division of Rosatom State Corporation. It is one of the leading Russian manufacturers in the field of power engineering and Russia's only industrial complex with a full production cycle: from its own production of metallurgical blanks to finished high-tech oversized products with the ability to ship anywhere in the world