AEM-Technologies, JSC has shipped tanks for safety systems to Akkuyu NPP

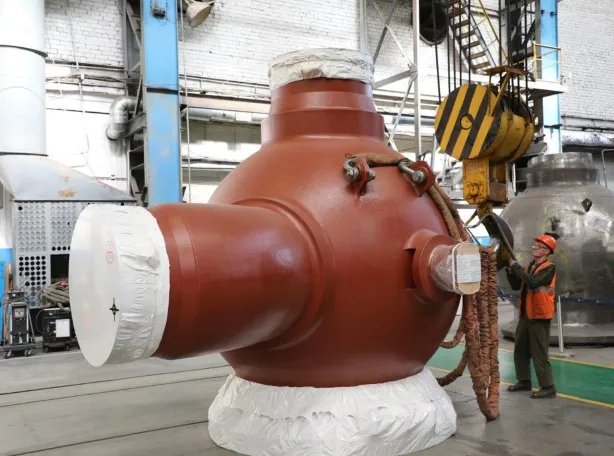

AEM-Technologies Izhora (a part of machine-building division of Rosatom - Atomenergomash) has shipped passive core flooding systems tanks for Akkuyu NPP Unit 2 (Turkey).

Eight PCFS tanks were dispatched to the first nuclear power plant in Turkey that is the exact number of tanks required for operation of the system. The outside diameter of each tank is 4.2 m, the length is 11 m, and the weight is 80 t.

The route to the site runs through the Baltic Sea, the Atlantic Ocean and then the Mediterranean Sea and makes up over eight thousand kilometers.

The PCFS is an important element of the NPP safety system. In worst-case situations in the primary circuit it removes residual heat. Water solution of boron acid heated up to 60 degrees is stored in the tanks. If pressure in the primary circuit drops below a certain level, the liquid is automatically supplied to the reactor to cool down the core.

Akkuyu NPP in Turkey is the first project in the world that is implemented according to the Build-Own-Operate model. The design includes four power units with Russian reactors of VVER-type, 3+ generation with enhanced safety and improved performance characteristics. The facility is designed by engineering division of the State Atomic Energy Corporation Rosatom. The power of each unit is 1200 MW.

According to the intergovernmental agreement between the Russian Federation and the Republic of Turkey, Unit 1 of the NPP shall be commissioned within 7 years after all the permits and licenses for the Unit construction have been obtained. Considering that the license for construction of Unit 1 was obtained in 2018, the commissioning is expected to be in 2025. But the participants of the project do their best to complete the construction of Unit 1 and to ensure the readiness for commissioning test in 2023, which is an anniversary year for the Republic of Turkey.