Izhora plant, AEM-Technologies, JSC has carried out hydraulic tests of the pressurizer for Kudankulam NPP

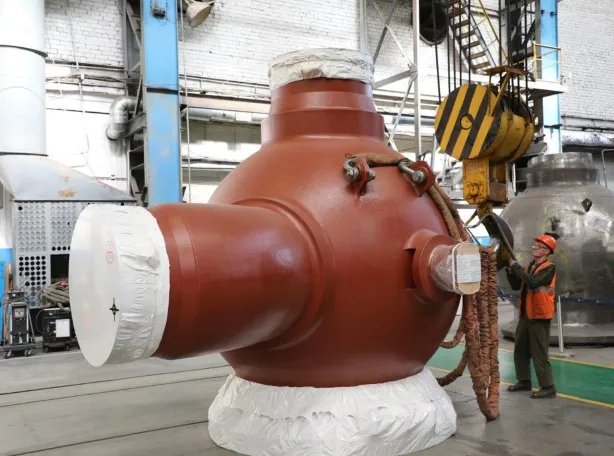

Pressurizer for Kudankulam NPP (India), Unit 5, manufactured by AEM-Technologies Izhora (part of Atomenergomash, the machine-building division of Rosatom) has passed hydraulic tests.

The pressurizer is part of the key equipment of the NPP reactor hall. The unit is designed to provide the necessary pressure in the primary circuit of the reactor. In the assembled condition, it is almost 14 m long and 3.3 m in diameter, the mass of the vessel is 187.5 t. Its internal volume is 79 cubic meters and the wall thickness is 152 mm.

During hydraulic tests, the vessel was subjected to tightness test at high temperatures. Water heated-up to 96 С was supplied to the pressurizer. At the same time, the pressure in the tank was increased to the maximum allowable value for this equipment, which is 24.7 MPa. The pressurizer has passed all the tests, retained the tightness and has been accepted by the commission. The equipment is being prepared for shipment.

Kudankulam NPP is the largest nuclear power plant in India, it consists of six power units, two of which have already been put into operation. The NPP is being built within the terms of the intergovernmental agreement between the Russian Federation and India, signed in 1998. Russian VVER-1000 type reactors are used in the project. The facility is designed by Engineering Division of State Atomic Energy Corporation Rosatom. The capacity of each NPP power unit will be 1000 MW.