Atommash has shipped equipment for the Turbine generator building of Akkuyu NPP, unit No. 2

Production site AEM-Technologies, Atommash (part of the machine-building division of Rosatom – Atomenergomash, JSC) has shipped Modules of tube system for the Steam-turbine condenser for Akkuyu NPP, unit No. 2.

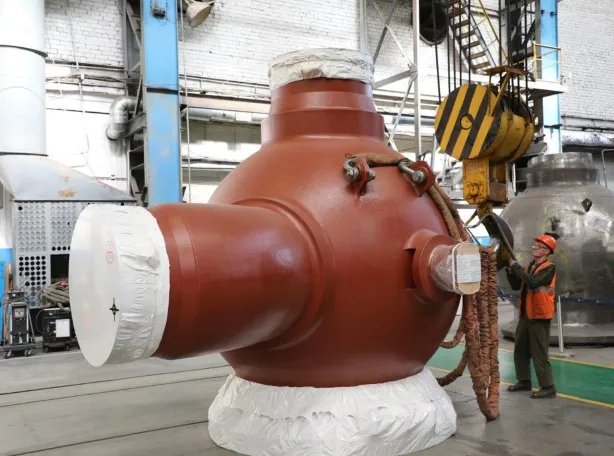

The Module of tube system is equipment that is part of the turbine condenser and is installed in the turbine hall of the nuclear power plant. The item consists of more than 14 thousand tubes arranged in a special order along the entire length of the Module. Sea water for cooling and condensation of steam that has passed through the turbine will be pumped through these tubes at Akkuyu NPP. The length of the Module is 16 meters, the height is 6 meters, the width is 4 meters. The weight of a Module of tube system is 125 tones. The delivery set includes 4 modules.

The final stage of equipment manufacturing is hydraulic test during which the Modules of tube system were set at an angle on the special support system, large plugs with the dimension of 4х6 meters were installed and fastened with studs. Then each item was filled with purified desalinated water, pressure was built up to the maximum level of 7.5 atmospheres, after that the Modules were held under the pressure for an hour. During the test, the strength and tightness of the Modules of tube system were confirmed.

The items will be transported to Akkuyu NPP by water, the total distance is 3000 km. Akkuyu NPP project includes four units with Russian generator III+ VVER reactors with the increased safety and improved technical characteristics. The capacity of each NPP unit is 1200 MW. The project engineering was performed by the engineering division of Rosatom State Corporation.

AEM-Technologies is the largest company within the structure of Atomenergomash, JSC - a machine building division of Rosatom State Corporation. It is one of the leading Russian companies in the field of power engineering, and the only Russian industrial complex with the full manufacturing cycle from its own production of metallurgical blanks up to completed advanced-technology oversized products that can be shipped to any part of the world.

Atomenergomash, JSC is a machine-building division of Rosatom State Corporation, one of the leading Russian power-engineering companies in terms of production and revenue. The holding is a single-source manufacturer of equipment for the reactor island and the turbine hall of all Russian-designed nuclear power plants under construction, a manufacturer of equipment for LNG projects, waste-to-energy processing plants, a developer and supplier of integrated solutions for energy, oil and gas, shipbuilding and other industries. Our technologies and equipment ensure the operation of about 20% of nuclear power plants in the world. The company unites leading research,