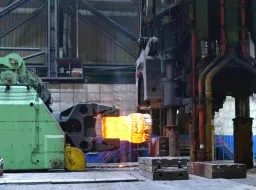

Press Forging

Forging is one of the key specialization profiles of AEM-Special Steels. The focus area of the forging complex is production of forgings for nuclear power industry. Up-to-date equipment makes it possible to produce forgings by open die forging practice weighing from 250 kg to 260 tons, made of special steel grades using ingots from 3 tons.

Equipment

Automated forging plant

| Description |

The forging plant with 12.000 ton-force capacity press is one of the largest in Europe. It is designed for forging ingots weighing from 32 to 443 tons and producing forged billets with a diameter of up to 5.5 m and a weight of up to 260 tons. The large-sized one-piece forged shells manufactured at the plant make it possible to achieve a minimum number of welds on the vessels for nuclear power industry equipment and zero welds in the reactor vessel core area.

|

| Main characteristics |

Maximum capacity of the press: 12,000 tf

Shape of manufactured products: regular solid products, irregular products, hollow products Maximum dimension between slabs: 3.050 m Maximum dimension between columns: 2.3 × 5.8 m Number of manipulators: 2 Load capacity of forging manipulator: 250 t Load capacity of tool manipulator: 5 t Weight of processed ingots: 32 – 440 t Weight of received forgings: 20 – 260 t Maximum forging length: 18 m Maximum productivity: 36,400 tons of forgings / year |

Production Capabilities

636 thousand tons

maximum annual production of steel of various grades

220 thousand tons

maximum annual production of forgings

> 300

the number of steel grades that the metallurgical complex can produce

260 tons

maximum weight of forgings available for production

In addition to an automated forging complex with a force of 12,000 tf, hydraulic presses equipped with cranes and manipulators with a force of 1,250 tf, 3,200 tf, and 6,000 tf are involved in forging blanks. The forging process is constantly monitored by a quality specialist. He monitors the geometry of the future product and strict adherence to the technological process of production.